News

Industrial Coating Inspection Company Using DJI M300 RTK

Europe’s largest coating inspection company launches drone inspection service - spearheaded by the DJI M300 RTK - to save money, increase safety and boost efficiency across sectors such as oil and gas, construction, renewables, marine, indu ... Read More

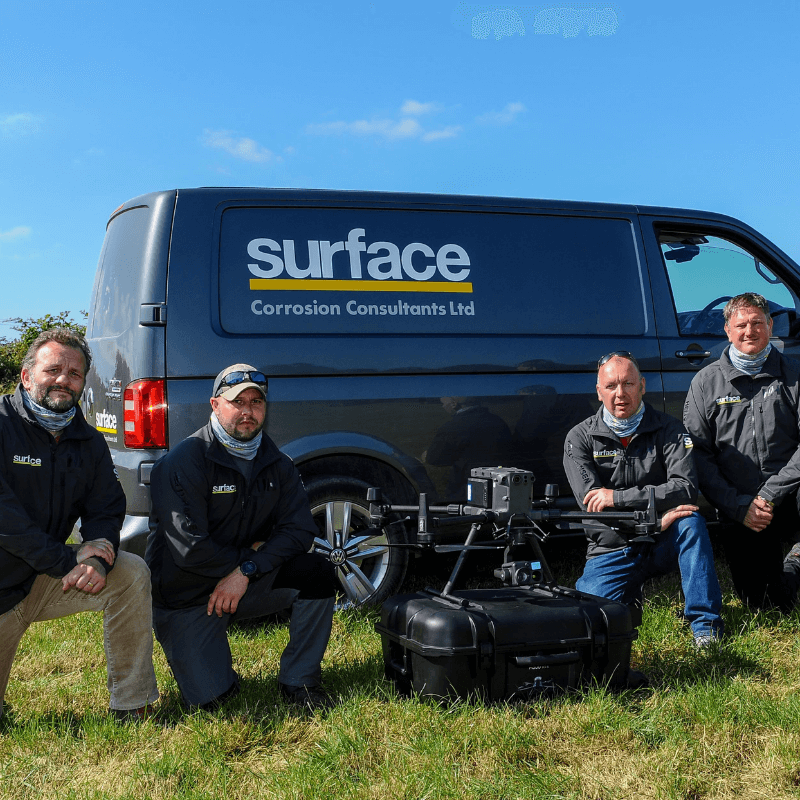

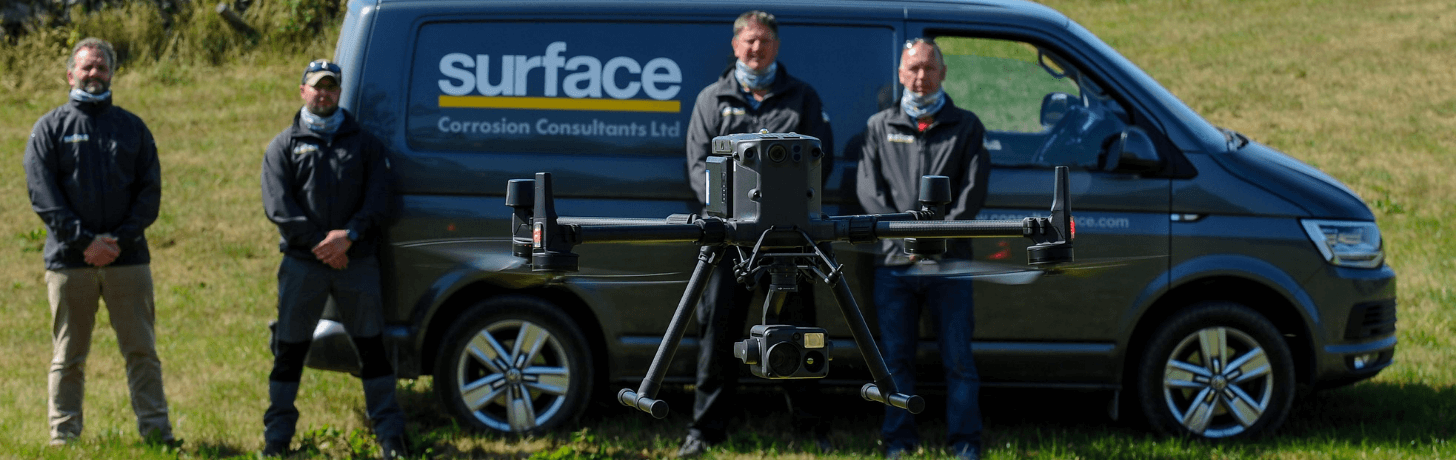

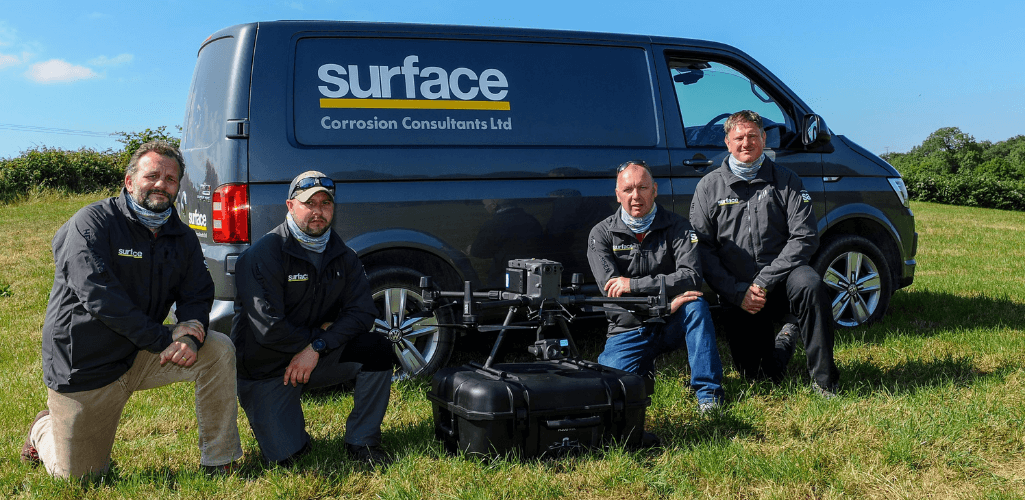

Major coating inspection company, Surface Corrosion Consultants Ltd, launches drone inspection surface, spearheaded by DJI M300 RTK;

The drone, coupled with the company's innovative SAM™ software, will provide real-time insights during onshore and offshore inspections;

Drone-based inspection reduces the need to shutdown critical assets and stops workers operating at height - reducing costs and improving safety;

M300 RTK praised for its stability, while the level of zoom on the H20T camera is described as 'unbelievable'.

Surface Corrosion Consultants Ltd says drones ‘provide a number of solutions to combat what were once potential issues within the inspection and coatings survey market’.

Europe’s largest coating inspection company has launched a drone inspection service - spearheaded by the DJI M300 RTK - which will transform operations for a number of cross-sector industries.

Surface Corrosion Consultants Ltd - headquarted in Belfast and specialising in comprehensive paint inspection, NDT Inspection and corrosion prevention - will be deploying its UAV service to monitor and inspect corrosion for its clients across the UK and Europe.

It will offer long-term benefits such as reduced overheads and operating costs, and health and safety benefits compared to traditional manual inspection survey methods.

heliguy™ has helped Surface Corrosion Consultants start the drone division, guiding four pilots through the GVC course - plus industry-specific photography and thermography training - and providing access to the M300 RTK.

The use of UAVs - which enable assets to remain operational during inspection - is quickly becoming the preferred technique for Coating & Paint Inspection across a wide range of sectors including oil and gas, construction, renewables, marine, industrial and transport and infrastructure.

heliguy™ caught up with Thomas Harrison, Executive Assistant to Directors at Surface Corrosion Consultants Ltd, to find out more about the service and how the M300 RTK will benefit inspections.

Drones For Inspection: Q&A With Thomas Harrison

Can you tell us more about your new UAV service?

UAV services relating to the inspection sector have seen huge advancement in recent times as companies begin to understand the benefits of incorporating this form of inspection into their maintenance and repair budgets.

Our team of experienced AMPP / ICorr qualified coating surveyors monitor, inspect, and survey assets, both onshore and offshore, using drones.

UAV inspection is a safe and efficient alternative inspection method which makes it possible to access areas that may pose risk from hostile working conditions including height, weather and radiation.

Furthermore, combined with our SAM™ software, our UAV inspection service offers transparent reporting and removes the need for manual data input.

How will drones be integrated into your existing workflows?

UAVs will be used to reduce the health and safety risks associated with inspection.

Inspections will follow the same processes but our inspectors will have their feet firmly planted on the ground. At this stage, we will be focusing on visual inspections and hopefully as technology develops we can incorporate different types of testing and inspection to our UAV service.

We have been able to link our UAVs with our in-house SAM™ software which allows for images taken by our UAVs to be seen within our reports which are sent directly to our clients.

Our inspectors can begin to understand defects and areas of concern whilst the drone is in flight, ultimately saving time and money on what could have previously required both a drone pilot and coatings inspector to conduct the survey, and we can use this information to implement a plan to support the next steps to protect an asset..

How will drones benefit your workflows/operations?

With cost pressure a growing concern among asset operators and industrial services companies, UAV-based asset inspection offers a new way to optimise cost and time savings, increase performance and quality, and thereby secure a competitive edge.

Our inspection team no longer has to be put into potentially dangerous situations, such as working at height. The drone can collect the data for us, with our staff safely on the ground and away from hazardous areas.

In short, drones can access hard-to-reach places faster, cheaper and with less risk than manual inspections, and potentially allow the asset to remain live.

Our ability to return an asset to operation quickly or prevent an asset from being taken out of service provides significant cost savings, reducing costs associated with isolating an area or shutting down an entire asset.

Further cost savings are achieved as companies generally no longer require a manual process such as rope access technicians, mobile elevating work platforms or scaffolds.

UAV inspection is also the safest alternative to any manned inspection survey method.

Essentially, UAV inspection can provide a number of solutions to combat what were once potential issues within the inspection and coatings survey market.

Why will the M300 RTK form an essential part of your operations?

Using a DJI Matice 300 RTK drone, our qualified coating surveyors are able to survey assets with the use of its onboard cameras.

This is the first step in the inspection process and allows inspectors to carry out a thorough inspection in a short period of time to assess an asset.

When paired with the H20T camera, the quality of images it can collect is unbelievable: Especially the zoom, which captures great imagery from far away.

This becomes hugely beneficial to us when we are flying around tricky surroundings: We can fly at a certain level and position and then engage the zoom to capture photographs of the relevant areas without risking the UAV crashing into beams and structures etc.

We maintain a constant drive for efficiency for our clients and believe that UAV inspection, together with our innovative SAM™ software, is a game changer for the future management of corrosion in the energy and construction industries.

The M300 RTK is IP45-rated. How important is this for offshore operations?

Stable aircraft are safer aircraft! When working offshore it’s difficult enough to traditionally inspect when exposed to the elements, so as we introduce innovation and technology to our business we need to make sure it’s to the safest possible standard.

What has your experience been of working with heliguy™ to start your UAV service?

heliguy™ has been great from start to finish. It was painless to get Jack (heliguy™ instructor) over to Northern Ireland to carry out the four-day training course, which included dedicated training on thermography and photography.

All four of our inspectors who carried out the training spoke very highly of the course and the way in which it was delivered.

The support has been great in understanding what UAVs we will require for our line of business and any queries we have can be settled at the other end of the phone.