Case Studies

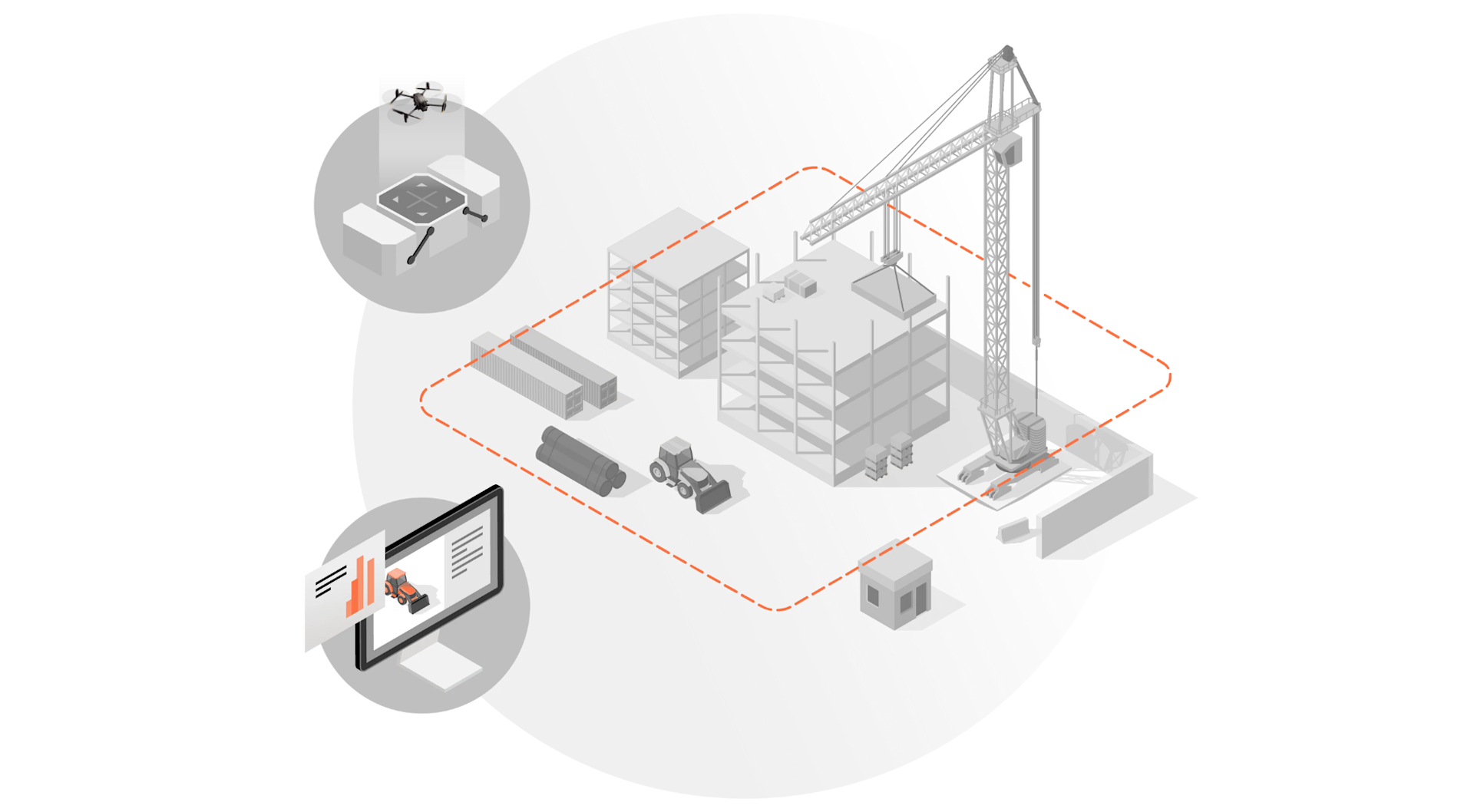

Drone in a Box for the Construction Industry

Unlock 24/7 site monitoring and real-time data capture with drone-in-a-box technology like the DJI Dock for construction and the AEC sector.

A drone-in-a-box system is a valuable asset for the construction and AEC sectors—boosting efficiency, improving safety, and providing real-time site insights.

The DJI Dock, Dock 2, and Dock 3 deliver fully automated, 24/7 aerial data collection for accurate progress tracking and reduced need for manual inspections.

Can be kept permanently on-site, these systems support remote scheduling and data access, cutting site visits and operational costs.

All Docks offer cloud-based control, fast charging, and all-weather performance, ensuring longer operational windows and consistent, high-quality data.

Dock 2 is built for surveying, while Dock 3 is optimised for mobile use as DJI’s first vehicle-mounted Dock. Both well suited to construction needs.

heliguy™ is authorised for BVLOS (Beyond Visual Line of Sight) operations and provides full support for deployment, compliance, and mission delivery.

A drone in a box can revolutionise the construction industry - enabling round-the-clock real-time data capture, improved safety, and centralising insights for remote monitoring.

Large-scale construction projects constantly require live information to help with asset management, site security, digital twin creation, and asset monitoring.

Deploying a remote access drone system, like the DJI Dock 3, Dock 2 or DJI Dock, can transform this workflow.

Benefits of a drone in a box for construction sites include:

24/7 Monitoring: Drone in a box systems are permanently onsite, meaning they can be deployed on-demand for round-the-clock data capture. This is useful for persistent scheduled data collection or for spontaneous, on-demand situational awareness: Useful for project monitoring or reacting to security breaches.

Automated Data Capture: There is no requirement for individuals to be onsite to capture data - improving safety, removing the associated administration, and providing operational flexibility.

Real-time Updates: Constantly update data streams to create a live environment, constantly evolving in tandem with the site. This is particularly useful for developing and updating digital twins.

Virtual Analysis: Immediately share and centralise data feeds from multiple sites for remote monitoring and cloud-based visualisation. This improves site-wide collaboration and decision-making on construction projects.

In this article, we'll take an in-depth look at how a drone in a box can be a transformative solution for the construction industry. We'll also explore how the specific features of the DJI Dock 3, Dock 2 and DJI Dock make these particular docking stations powerful solutions for the AEC sector.

We'll also cover how heliguy™ can work with construction companies to conduct BVLOS Dock operations on their behalf to help accelerate adoption of drone in a box technology.

What is a drone in a box?

A drone in a box is a fully automated drone that is housed in a protective box when not in use.

The box is designed to provide shelter for the drone when it is not operational and can also serve as a launching/landing pad and a charging hub.

The drone in a box is programmed to take off, fly a predetermined route, and return to its box autonomously, without the need for a pilot.

The DJI Dock collection is engineered to operate 24/7. The drone lands, recharges, takes off, and executes missions programmed remotely in DJI FlightHub 2.

The Dock 3 is compatible with the M4D Series and unlike the Dock 2 drones, these can operate independently from the Dock - ideal for drone-relay operations.

The Dock 2 houses the M3D Series, while the DJI Dock is deployed with the DJI Matrice 30 Series.

We'll discuss the DJI Dock ecosystem in more detail later in this article. However, it's worth noting that when it comes to construction, the DJI Dock 2's M3D drone is a dedicated drone-in-a-box survey solution, while the DJI Dock 3 with M4D is a strong contender if you need extra flexibility and transportability for your deployments.

Benefits Of using a drone in a box in the construction industry

Using a drone in a box has multiple benefits for the construction industry. These include:

Increased efficiency

Permanently-sited on-location: A drone in a box is ready to deploy on-demand and flights can be automated.

This increases efficiency by being able to immediately collect data at a moment's notice and reduce the logistical burden of sending personnel and equipment to site for specific missions.

Repeatable data

Automate missions to ensure on-site robots collect accurate and repeatable data, more frequently. This reduces human error and is ideal for change monitoring and progress monitoring, helping to spot defects early to reduce costs and downtime.

Operational flexibility

A drone in a box can be deployed to conduct persistent, scheduled, round-the-clock data collection or to gather spontaneous, on-demand situational awareness.

A remote monitoring ecosystem is unbound by the availability of pilots or employees, and can be controlled remotely through cloud-based management.

Improved safety

Construction sites can be dangerous. Using a drone in a box can help to minimise the risks associated with manual labour.

Drones can collect data in areas that are difficult or dangerous to access for humans, reducing the need for workers to physically access these spots.

Drones can reach otherwise inaccessible zones, capturing data which would be missed or unavailable using alternative methods.

Cost-effective

A drone in a box can be a cost-effective alternative to traditional surveying and monitoring methods. It can reduce labour costs and improve accuracy and efficiency, resulting in a more cost-effective construction process.

A docking station is constantly positioned on-site, reducing the costs associated with personnel travelling to the site.

Reduce operational costs and maintain business continuity and operations from anywhere in the world as on-site robots collect consistent, accurate and repeatable data - all managed from afar, centralising data.

Environmental benefits

The construction industry is a major contributor to global carbon emissions. However, a drone in a box system can help construction projects transition to a more sustainable and low-carbon future.

A docking station runs on electric power, which can reduce fuel consumption and greenhouse gas emissions associated with traditional construction machinery and vehicles.

Because it is located on site, a drone in a box reduces site visits, helping to cut the number of visits by car to reduce traffic congestion and associated emissions.

The quality, accurate, and repeatable data collected by drones optimise site planning, reduce waste, and minimise errors: This helps to use construction materials more efficiently and minimises the need for rework.

To find out more, read our blog entitled: How drones can help the construction industry become carbon neutral.

Applications of a drone in a Box in the construction industry

A drone in a box, like the DJI Dock, can collect a range of data on a construction project.

Progress monitoring & site planning

A drone in a box can capture high-resolution imagery and real-time data to monitor construction progress and make better data-driven decisions.

Benefits of monitoring progress on a construction site include:

Improved Project Scheduling: By monitoring the progress of construction activities, project managers can identify potential delays and adjust the schedule accordingly to ensure that the project stays on track.

Enhanced Communication: Progress monitoring can facilitate better communication between project stakeholders, including contractors, subcontractors, architects, and project owners. This helps to keep everyone informed about the status of the project and ensures that any issues are addressed in a timely manner.

Improved Quality Control: Monitoring construction progress can help identify any quality issues early on, allowing for quick corrective action. This can help to prevent costly rework and ensure that the final product meets the required quality standards.

Cost Savings: By identifying potential delays, quality issues, and safety hazards early on, progress monitoring can help to prevent costly rework and delays, ultimately saving time and money.

Located on-site, capable of deploying on-demand, and collecting repeatable, real-time data, a drone in a box is a useful solution for project monitoring.

This is also beneficial for site planning and design, using data to optimise the use of construction materials and reduce waste.

Safety and security

Security on any construction site can be a challenge, requiring large amounts of manpower and technology to cover every corner.

A drone in a box provides an efficient, effective and round-the-clock method of security.

Benefits include:

Deploy during periods when human security personnel are not present, reducing the requirement for human resources and providing 24/7 security;

Automated drone surveillance provides a mobile CCTV system, able to cover huge areas quickly and regularly;

A drone in a box can be programmed to fly around the perimeter of a site, monitoring for potential security breaches or safety risks;

Can be deployed in the event of an emergency, responding to alerts;

Provides real-time footage, which can be accessed remotely;

Drone surveillance, automated perimeter inspections and remote access video feeds are a huge deterrent to intruders and are a key element of any high-end security system.

Drone in a box vs traditional drones for construction

The construction industry is already benefiting from drones - increasing efficiency and improving site safety, compared to traditional methods.

However, these gains can be stretched further when deploying a drone in a box, as solutions like the DJI Dock 2 and DJI Dock offer several advantages compared to traditional drone deployment. These include:

Increased safety and security

A drone in a box is designed to take off and land automatically from a secure and stable location, reducing the risk of accidents that can occur during manual take-off and landing.

Remote deployment means that the drone can collect data where it may be difficult to manually launch and land a drone.

The box also provides a haven for the drone, reducing the risk of theft or damage. The box can also be locked for added security.

Automated Operation

A drone in a box can be programmed to conduct automated operations, which means it can take off, fly a predetermined route, and land without the need for a pilot.

It can also be deployed remotely, unburdened by lack of human resources.

This enables more efficient, accurate and round-the-clock operations, for on-demand or pre-planned data collection.

Protection from the elements

The box provides protection for the drone against environmental factors such as rain, wind, and dust. This can prolong the lifespan of the drone and reduce the need for repairs or replacements.

A drone in a box is typically designed to withstand wear and tear, making it more durable than a normal drone.

How the DJI Dock can benefit the construction industry

The case for using a drone in a box for the construction industry has been made.

But how specifically can the Dock 3, Dock 2 and DJI Dock benefit the AEC sector?

It's worth stating that while the DJI Dock can be used for construction jobs, the DJI M3D is DJI's first dedicated drone in a box survey solution, making it perfect for the AEC industry.

Meanwhile, DJI Dock 3 is the first vehicle-mounted option, offering flexible deployment and the ability to run dual-drone rotations from a single setup, ideal for mobile and large-scale construction environments.

Reliable and rugged

The DJI Dock and DJI Dock 2 are IP55 rated. Dock 2 has an operating temperature of and has an operating temperature of -25° to 45° C, while DJI Dock can operate in temperatures ranging from -35°C to 50°C.

Dock 3 is IP56 rated, giving it even more durability than its predecessors.

All Docks can be deployed round-the-clock and have an integrated weather station, which knows when conditions aren't safe for the drone to fly.

Rapid deployment

Both the DJI Dock 2 and DJI Dock have fast-charging capabilities, enabling rapid and almost constant deployment. This availability is useful for construction projects, collecting data on-demand: Especially useful for feeding into digital twins and collecting data for constant and up-to-date progress monitoring.

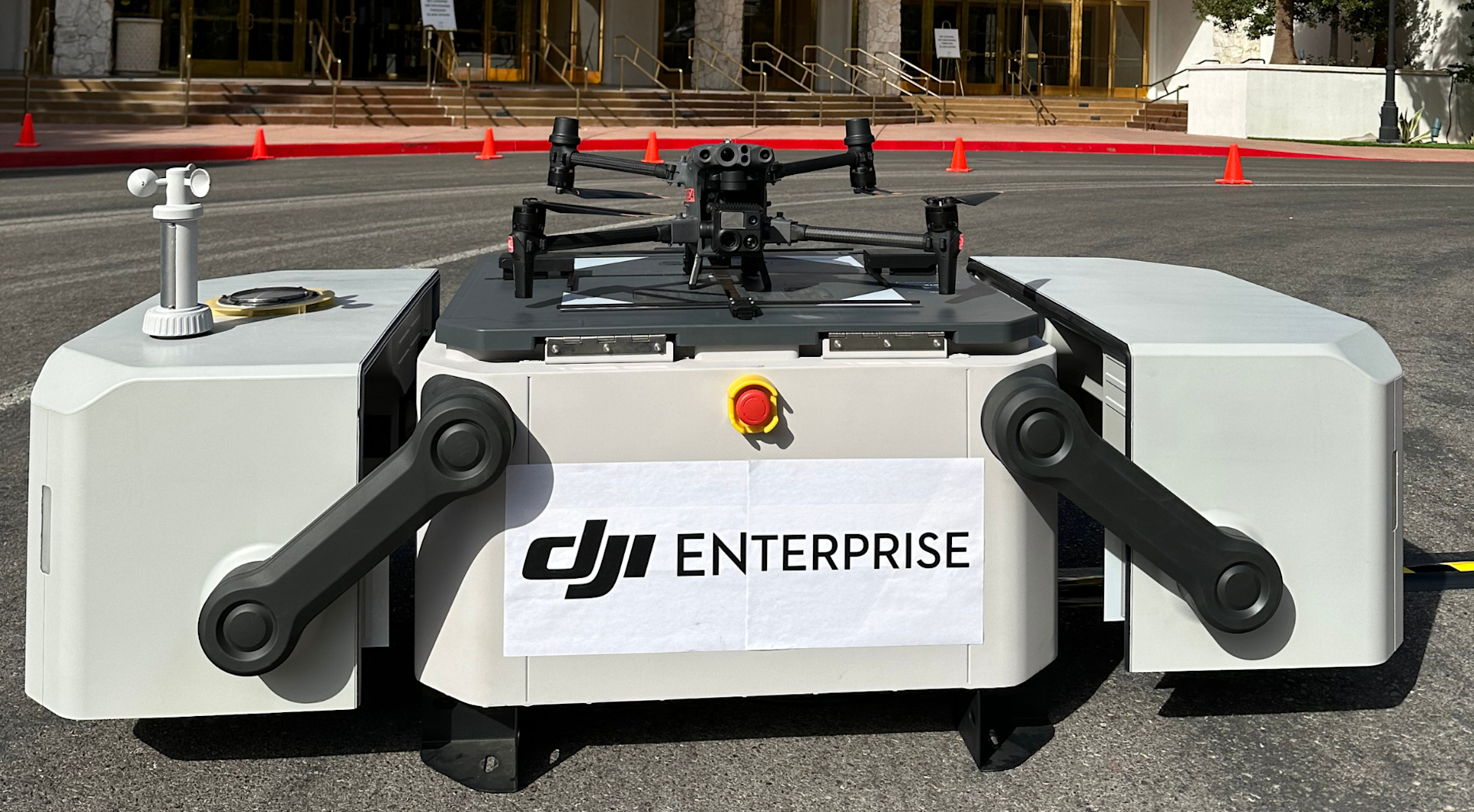

Though it has to be stated that Dock 3 has the most rapid deployment—capable of launching in as little as 10 seconds. It’s also optimised for mobile use, with the ability to be vehicle-mounted and support dual-dock setups for continuous mission rotations.

DJI Dock 3 for construction

DJI Dock 3 is made for mobile construction work. It’s the first Dock that can be vehicle-mounted, making it easy to move between sites and set up quickly.

The DJI M4D is built for precision mapping and inspections. It’s equipped with a wide-angle, medium tele, and 168mm tele camera—perfect for capturing detailed site data and tracking progress. With FlightHub 2, operators can use auto-zoom tracking to follow moving vehicles or equipment on site.

For thermal imaging and night operations, the DJI M4TD includes a six-sensor payload with a thermal camera, laser rangefinder, and night vision. Ideal for low-light conditions and detailed data capture.

Dock 3 is IP56-rated for tough conditions and supports dual-dock setups for non-stop operation. Perfect for busy, fast-moving construction projects.

DJI Dock 2 for construction

When paired with the DJI M3D, the DJI Dock 2 is DJI's first dedicated drone in a box for surveying - making it perfect for the construction industry.

The DJI M3D features a 20MP 4/3 wide-angle camera with a mechanical shutter. It is also equipped with a 12MP tele camera with 56x hybrid zoom. This makes the drone ideal for tracking project progress and collecting data for volumetric calculations, while the tele camera can be used for inspection purposes.

The DJI M3TD for Dock 2 is not optimised for surveying, but comes with visual and thermal sensors, including an infrared sensor with a 640 x 512 normal resolution, and 1280 x 1024 in UHR infrared imaging mode.

Both the DJI M3D and M3TD have a flight time of up to 50 minutes and an operation radius of 10km.

DJI M30 Dock Version for construction

Fully charged, the M30 flies can fly for 40 minutes and can conduct missions and inspections up to 7km from the Dock.

The M30 Series Dock Version integrates wide, zoom, and thermal cameras (the thermal is on the M30T version). This data can be used for project tracking, while the thermal sensor is ideal for checking for leaks and the integrity of buildings on-site.

Click the hyperlink to find out more about the key features of the DJI Dock.

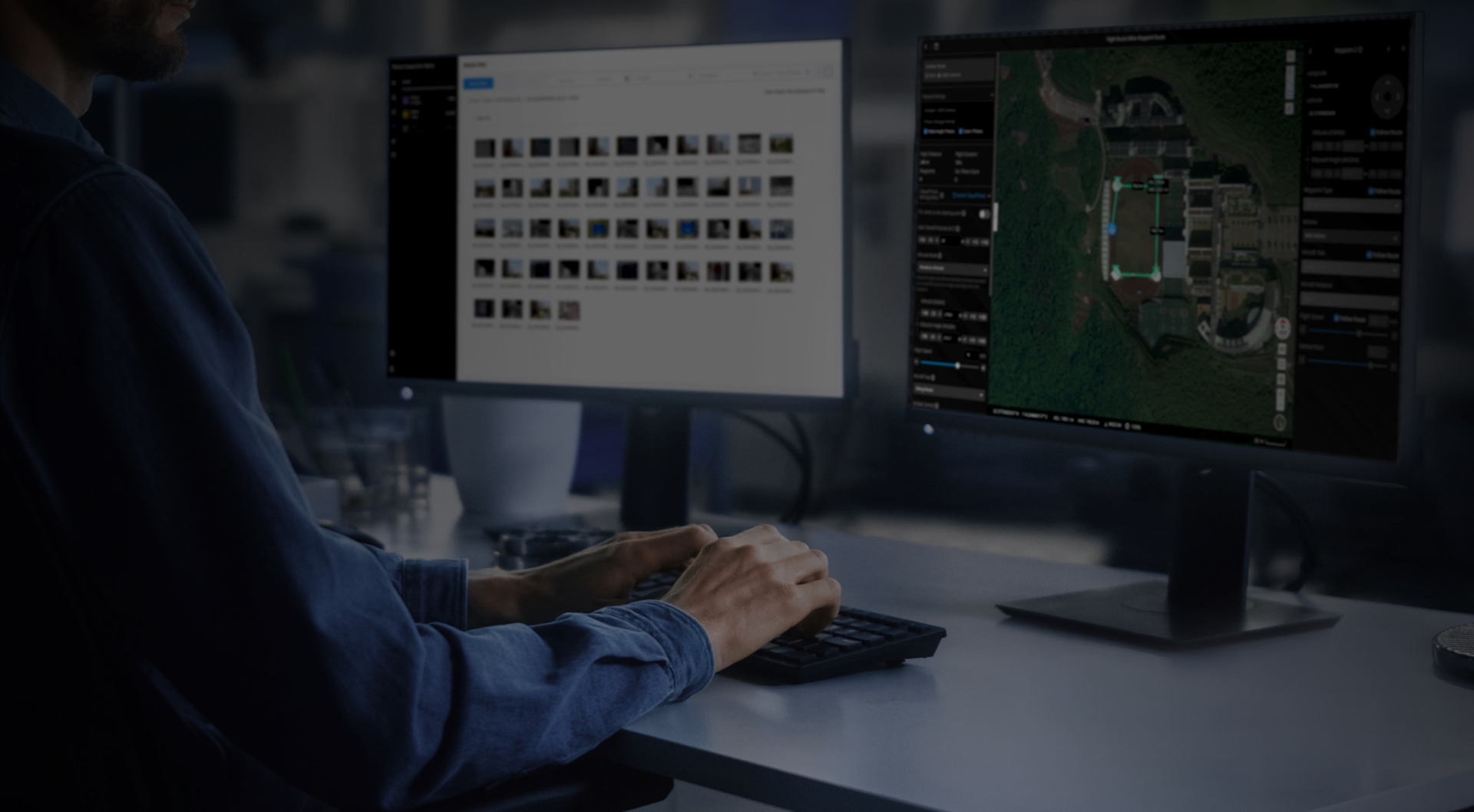

Cloud Management

DJI Dock 3, Dock 2 and DJI Dock can be controlled remotely via the DJI FlightHub 2 platform. Schedule missions, create and edit flight routes, and manage the collected data.

Remote monitoring and flight planning improves site-wide collaboration on construction projects, and improves sustainability by removing the number of required site visits.

To find out more about FlightHub 2, read our Key Features Of DJI FlightHub 2 Drone Management Software blog.

Additionally, there is a FlightHub 2 On-Prem version available, allowing organisations to store their data locally on their own servers. Read our FlightHub 2 On-Premises: Enhanced Drone Data Security blog to learn more.

Drone In A Box For Construction: Rules In The UK

So, what are the legal considerations when deploying a drone in a box in the UK?

As things stand, there is nothing stopping operators from flying a drone from a box. But there are limitations.

Organisations who do not yet have BVLOS (Beyond Visual Line of Sight) permissions will first need to operate VLOS (Visual Line of Sight).

For more details about working towards BVLOS permissions, including completing a UK SORA* application and the current state of play regarding BVLOS operations in the UK, read our DJI Dock: Building Your Safety Case And UK BVLOS Pathway blog.

However, heliguy™ has permission to conduct DJI Dock flights BVLOS and can work with organisations to conduct this type of mission on their behalf. Read the next section to find out more.

*The UK SORA replaces the OSC methodology and aligns the UK with internationally-recognised standards.

heliguy™ Permission For BVLOS Dock Operation

heliguy™ has obtained permission to conduct BVLOS Dock operations in an atypical air environment - and can work with construction organisations to fly BVLOS missions on their behalf. Find out more here.

Operations can be conducted remotely by the heliguy™ pilot team from the Remote Operations Control Centre (ROCC) at heliguy™ HQ, or from the heliguy™ Drone Command Unit - a fully-equipped mobile control room.

This enables construction organisations to accelerate their adoption of drone in a box technology to benefit from remote and automated data collection.

Summary

A drone in a box offers a range of benefits for the construction industry, including increased efficiency, improved safety, and cost-effectiveness.

With the ability to collect high-resolution data quickly and accurately, a remote drone system can be used for progress monitoring, inspection and maintenance, site planning, and safety and security.

As the construction industry continues to evolve, a drone in a box is likely to become increasingly important in improving efficiency, safety, and sustainability.

And utilising the DJI Dock ecosystem offers a rugged and reliable drone in a box solution for the AEC sector.

Contact us

heliguy™ is a DJI Dock partner and can support you through every stage of setup, from initial consultation to ongoing after care.

Get in touch to find out more about the DJI Dock collection and how heliguy™ can support your adoption of this drone in a box, including training (such as UK SORA consultancy and EVLOS/BVLOS training), installation, site planning, and also conducting BVLOS operations on your behalf.