Technical

What is a datum point in surveying and drone mapping?

Learn what a datum point is in surveying and drone mapping, including vertical and horizontal datums, common mistakes, and how to avoid costly errors.

This blog explains what a datum point is and how it’s used in surveying and drone mapping;

Covers vertical and horizontal datums and how they affect height and position data;

Shows why datum mismatches are a common cause of survey and drone mapping errors;

Provides practical examples of how datum points are applied on real projects.

Understanding what datum points are is key to accurate surveying and modern drone mapping.

Whether you work in construction, utilities or infrastructure, consistent height and position data rely on clear reference systems.

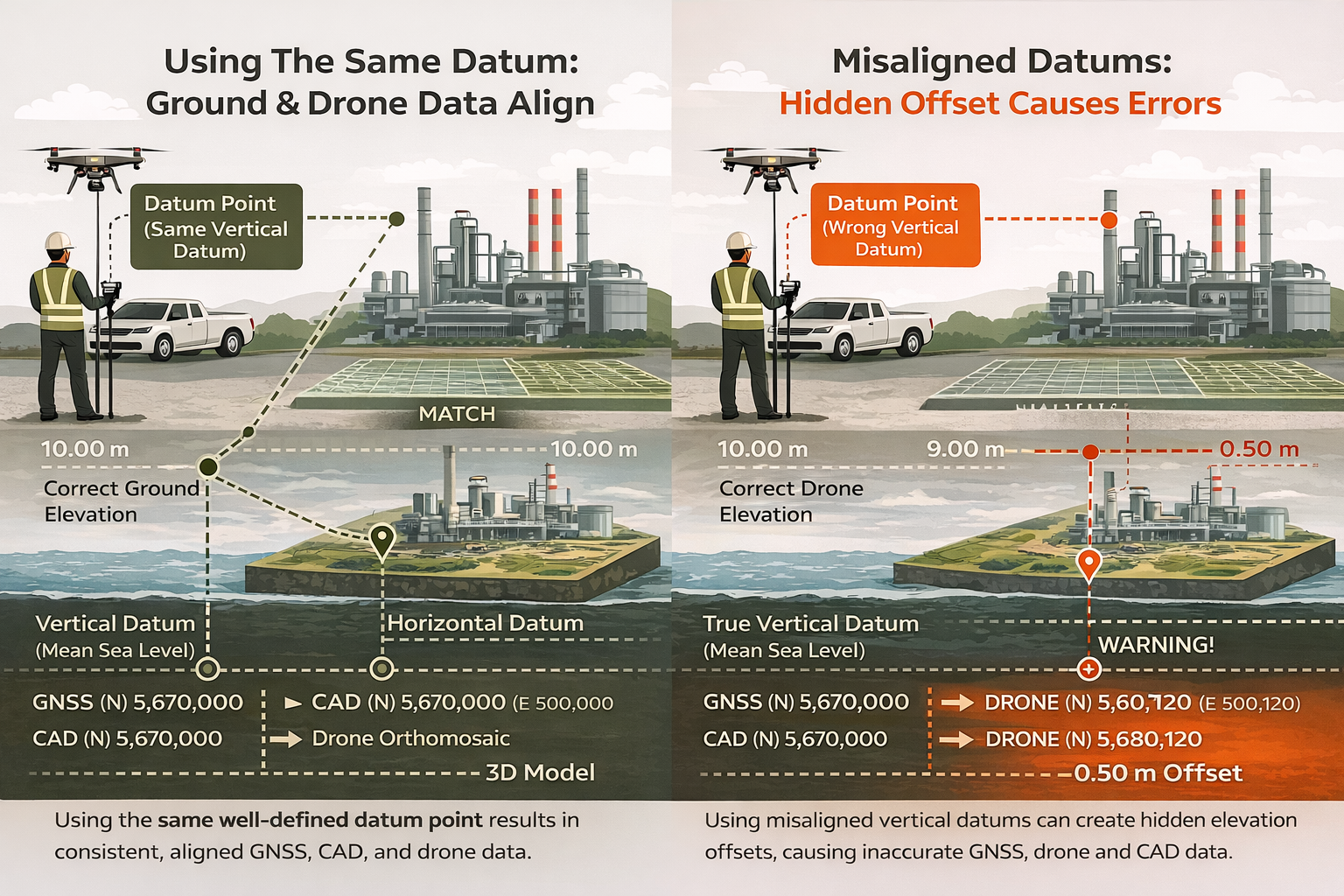

Misaligned datums remain one of the most common causes of survey error, especially when mixing ground, drone and design data.

In this blog, we will cover what a datum point is, why datum points are important, and provide examples of how they are used in real projects.

heliguy™ has an in-house survey department and can help you get started with drone mapping. Contact us.

Key takeaways

Datum points are fixed reference markers that keep survey and drone mapping data aligned.

They connect your site data to the correct vertical datum (heights) and horizontal datum (coordinates).

Using the wrong datum can create hidden offsets that lead to measurement errors, rework and delays.

Agree and document datums early to ensure GNSS, drone, CAD and GIS datasets all match.

Expert insight

“Most survey problems don’t come from the drone or the software — they come from mismatched reference systems. If your datum isn’t agreed and documented from day one, small offsets quickly become expensive rework — so understanding datums early protects accuracy, programme time and project costs. It is the foundation of reliable drone mapping.” — Alex Williams, heliguy™ Technical Geospatial Specialist

What is a datum point?

A datum point is a fixed reference used to measure height or position, so all survey data lines up correctly.

It links to a wider datum, which defines how height or horizontal position is measured, and provides the starting point for all other measurements.

Datum points form the foundation of consistent surveying workflows, whether you use traditional instruments or modern RTK/PPK drones, keeping coordinates and elevations accurate across a project.

Datum point vs benchmark vs control point vs GCP

Although these terms are sometimes used interchangeably, they refer to different types of reference points in surveying and drone mapping.

Understanding the difference helps prevent confusion when project teams share data and agree site control.

Datum Point: The reference point that ties a project’s measurements to a known vertical or horizontal datum. It ensures every dataset uses the same baseline for heights and coordinates.

Benchmark (BM): Typically a fixed physical mark used to transfer and check height on site. Benchmarks are often linked to a vertical datum such as Ordnance Datum Newlyn, but many sites also use local benchmarks to control levels during construction.

Control Point: A surveyed reference point used to establish the site grid. Control points are used for setting out, aligning datasets, and validating survey accuracy. In drone mapping, control points may also be used to confirm that drone outputs align correctly with engineering coordinates.

Ground Control Point (GCP): A visible marker used specifically to improve and validate drone mapping accuracy. GCPs are measured on the ground (often with GNSS or total station) and used during processing to ensure the orthomosaic, point cloud, or surface model matches the real world.

In most professional workflows, datum points, benchmarks, control points and GCPs work together, but they serve different roles.

Vertical datums for height and elevation

A vertical datum sets the reference for elevation.

In the UK, most heights use Ordnance Datum (OD), based on mean sea level at Newlyn. Surveyors and drone operators rely on this to ensure surface models and building levels match engineering requirements.

Knowing the correct datum is essential when combining data from different sources.

Horizontal datums for position and coordinates

A horizontal datum defines the coordinate system for eastings and northings.

Common examples include OSGB36 in the UK and WGS84 for GNSS and drone mapping.

Using the right horizontal datum ensures drone data aligns properly with existing CAD, GIS, and asset records.

Common causes of datum mismatch in drone mapping

Datum issues are one of the most common causes of survey error, especially when drone data is combined with CAD, GIS and historical site information. In many cases, the drone survey itself is accurate — but it has been referenced to a different datum than the rest of the project. Some of the most common causes of datum mismatch include:

WGS84 vs OSGB36 confusion: Drone and GNSS systems often default to WGS84, while most UK engineering and mapping workflows use OSGB36. If datasets are not transformed correctly, coordinates can shift and fail to align.

Ellipsoidal vs orthometric height differences: GNSS can output height relative to an ellipsoid, while most projects require height relative to a vertical datum such as Ordnance Datum Newlyn. If the wrong height reference is used, surfaces and levels can be offset.

Local site datum vs national datum: Some projects use a local benchmark or arbitrary site datum for construction convenience. If this isn’t documented clearly, drone outputs can appear “wrong” even when the survey is technically consistent.

CAD drawings and models created in different coordinate systems: Design data may be produced in a local grid, while drone mapping is captured in a national system. Without a clear transformation workflow, overlays can drift or rotate.

Inconsistent export settings from software: Even when capture is correct, exporting outputs in the wrong coordinate system, units or height reference can cause misalignment.

The most effective way to prevent these issues is to agree the datum early and document it clearly before any drone flights or survey work begins.

Why survey datums matter for accurate measurements

A survey datum provides a shared reference frame so that every height, coordinate and model sits in the right place.

When teams exchange CAD drawings, drone outputs or GIS layers, the datum ensures each dataset lines up correctly.

Without this common reference, measurements drift, surfaces misalign and design models fail to match the real world.

How datums affect drone survey outputs

Datums do not just affect coordinates on a screen — they directly affect the accuracy and usability of drone deliverables.

If the datum is incorrect or inconsistent, outputs may look visually correct but fail when compared against engineering data or design models.

Common drone deliverables affected by datums include:

Orthomosaic maps: A misaligned horizontal datum can shift an orthomosaic so that it no longer matches CAD drawings, asset registers or GIS layers.

Point clouds and 3D models: Incorrect vertical datums can cause point clouds and models to sit too high or too low, which can create false clashes when compared to design information.

Digital Surface Models (DSM) and Digital Terrain Models (DTM): Height reference errors can affect terrain modelling, drainage analysis and planning outputs.

Cut-and-fill volumes and stockpile calculations: Small datum errors can significantly affect volume results, especially across large areas. This can lead to incorrect reporting and costly decision-making.

In most cases, these problems do not come from the drone itself. They come from using a different reference system than the rest of the project data.

How small height errors become big project risks

Even a small height error at the datum level can grow into a major problem as a project progresses.

A mismatch of only a few centimetres can affect cut-and-fill volumes, clash detection, drainage design and structural levels.

These errors often appear late in the programme, when rework is costly and delays impact wider operations.

How datum points are created and used on real projects

Surveyors establish datum points using GNSS, total stations or existing site control.

These points act as the backbone for both ground and drone measurements, forming a stable reference for all future work.

Benchmarks, control points and site grids

A benchmark level in construction is typically a permanent mark used to check and transfer heights.

Control points define the site grid and tie the project to the correct coordinate reference system.

Drone mapping also uses these markers to validate accuracy and ensure outputs match engineering tolerances.

Datum points: Real-world examples across industries

Datum points support accurate measurement, alignment and data integration across construction, utilities, infrastructure, energy and inspection workflows.

Industry | How datum points are used | Why it matters |

|---|---|---|

Construction | Control floor levels, set out structural elements, and support cut-and-fill analysis and progress surveys. | Prevents level mismatches that cause rework, drainage issues, and costly delays when designs meet real site conditions. |

Utilities | Map buried assets and align them with existing networks using consistent height and coordinate references. | Reduces the risk of mislocated assets, improves safety, and ensures drone/GNSS data matches existing GIS records. |

Infrastructure | Integrate drone surveys with LiDAR, GNSS and historical mapping using accurate vertical and horizontal datums. | Ensures datasets line up across time and systems, enabling reliable comparisons, modelling and decision-making. |

Energy | Track ground change, monitor assets and support infrastructure planning using stable reference points. | Makes change detection dependable over repeat surveys and supports planning based on consistent, repeatable measurements. |

Inspection | Align drone outputs with asset registers and engineering coordinates for reliable reporting. | Ensures findings can be referenced back to the right asset locations, improving traceability, compliance and maintenance planning. |

Practical checklist: how to avoid datum errors on a project

If you are using drone mapping alongside traditional survey methods, the easiest way to avoid errors is to confirm and document the datum information early. This prevents costly rework later when datasets are combined.

Before capturing or processing drone survey data, confirm:

The vertical datum being used (e.g., Ordnance Datum Newlyn or a defined site benchmark).

The horizontal datum / coordinate system (e.g., OSGB36, WGS84, or a local grid).

The units required for outputs (metres vs millimetres).

Whether the project requires GCPs or site control to validate accuracy

That all outputs are exported in the correct reference system for CAD/GIS integration

Taking a few minutes to confirm these details at the start of a project can prevent misalignment issues that otherwise only become visible once the data is in design workflows.

Working with Ordnance Survey and Ordnance Datum in the UK

Many UK projects adopt Ordnance Survey coordinates and Ordnance Datum heights.

This improves interoperability with national mapping, asset records and digital twins.

Converting between site grids and national grids requires careful management to avoid introducing coordinate shifts or elevation errors.

Datums, drones and modern geospatial workflows

Drone mapping systems depend on accurate datums to produce reliable outputs.

Misunderstanding the datum setup is a common cause of misalignment when bringing orthomosaics, point clouds or terrain models into CAD or GIS.

How RTK and PPK drones use datums and coordinate systems

RTK and PPK drones record position data in global systems, such as WGS84, but can output coordinates in local survey grids.

This ensures site models match ground control and engineering designs.

When working with enterprise platforms such as the DJI Matrice 400, RTK workflows link drone coordinates to the chosen vertical and horizontal datums for consistent accuracy.

Common mistakes when importing survey data into CAD or GIS

Typical issues include applying the wrong grid, assuming all data uses Ordnance Datum, mixing units or failing to apply the correct geoid model.

These mistakes cause vertical offsets, skewed overlays or misaligned layers. Checking the datum for each dataset before import is the most effective way to prevent rework.

heliguy™ enterprise support

heliguy™ provides end-to-end support to organisations adopting drone workflows, from choosing the right hardware to managing accurate data integration.

Our enterprise drone solutions and training programmes help teams understand datums, coordinate systems, RTK workflows and data handling, reducing the risk of errors when combining survey datasets.

Contact us today to learn how we can strengthen your surveying workflows with the right tools and expert training.

Conclusion: Why datum points matter in drone mapping

Datum points sit at the centre of accurate surveying and drone mapping. They provide the reference that ensures heights, coordinates and models all relate to the same real-world position, regardless of whether data comes from GNSS, drones, CAD or GIS systems.

When datums are clearly defined and consistently applied, drone outputs align cleanly with design data, asset records and engineering models. When they are not, even small mismatches can introduce hidden offsets that grow into costly errors later in a project.

Understanding what a datum point is — and confirming it at the start of every survey — is one of the simplest ways to protect accuracy, reduce rework and ensure drone mapping delivers reliable, usable results.

Frequently Asked Questions

What is the difference between a datum and a benchmark in surveying?

Why are datum points important for drone surveys and mapping?

What is the difference between a vertical datum and a horizontal datum?

How do surveyors choose a datum point on a construction site?

What is Ordnance Datum in the UK?