News

Turn your ideas into reality - Heliguy launches R&D service

Heliguy unveils new research and development service, offering bespoke product development, custom senor integration and UAV workflow consultancy. ... Read More

Heliguy has launched a new research and development department - to create bespoke items and offer custom-built solutions for commercial and enterprise drone missions.

HECTIC - which stands for Heliguy Electronics and Custom Technology Integration Centre - is based at our North East England HQ and will turn people's exciting ideas into reality.

Using their many years of experience and expertise in the UAV industry, our dedicated and knowledgeable technicians have launched this invaluable consultancy to provide tailor-made products and hardware and software integrations.

HECTIC champions a fresh perspective on custom technology creation and integration, catering for each and every individual's needs as they arise, providing access to brand new technology thanks to our team of experienced engineers.

Ross Embleton, Heliguy's Research and Development Associate

HECTIC already has a track record of helping clients in need and coming up with novel ideas to fix a problem. Solutions so far include integrating a hyperspectral camera with a DJI M600 Pro and mounting a Parrot Sequoia sensor onto a DJI Phantom 4.

So, if you have a solution to a problem in mind, but do not know how to produce it, that’s where HECTIC comes in.

If you would like HECTIC to help you, then please submit an inquiry

What can HECTIC do for me?

![]()

Bespoke Product Development

![]()

Custom Sensor Integration

![]()

UAV Workflow Consultancy

HECTIC comprises a highly-skilled team, capable of in-house manufacturing, 3D printing and extremely quick concept/prototype designs and visual representations, as well as the ability to meet clients’ needs within budget.

IMG_4304-700x394.jpg

IMG_4307-700x394.jpg

Bespoke Product Development: HECTIC can design and produce intelligent modules that solve specific problems for customers.

Camera onto a DJI M600

Examples include maintaining the centre of gravity for large cameras on three-axis gimbals, data-amalgamation boards from multiple sensors into a single data stream and smart landing pads for accurate landing in confined locations.

Custom Senor Integration: HECTIC can design and produce custom mounting, carrying and power solutions for custom payloads on all DJI drones.

A LiDAR system integrated with a DJI M600 Pro

Integrating multiple sensors onto a DJI M600 Pro

If you would like HECTIC to help you, then please submit an inquiry

These solutions can use external batteries or take power from the drones and can be mounted using specially-designed brackets made from metal or plastic, depending on the payload.

Parrot Sequoia sensor attached to a DJI Phantom 4

UAV Workflow Consultancy: HECTIC can design and produce tools that aid pilots to reduce ground time in jobs, perform maintenance on their drones and keep their equipment healthy. These tools include custom storage solutions and drone-cleaning kits.

Custom-made hot-swopper tool for the DJI Inspire 2

HECTIC Help - Case Studies

Heliguy's R&D team already has a track record of helping clients in need by coming up with novel ideas to fix a problem. Here are some examples:

Integrating a Hyperspectral Camera with a DJI M600 Pro

HECTIC created a comprehensive custom build for leading videographer and photographer David McArthur, of Hummingbird Technologies - an artificial intelligence company for arable farmers. Our team integrated a hyperspectral camera onto a DJI M600 Pro.

We designed a custom power supply utilising the power output of the Ronin-MX gimbal alongside an intelligent trigger system allowing the camera to take sophisticated and high-tech images autonomously and manually. Thanks to the intuitive design, the hyperspectral camera can be removed quickly and stored for transport.

We also integrated an ambient light sensor and GPS to the top of the drone, allowing the camera to encode GPS information into the images. This means that software, such as Pix4D, can be used to create composite images of large areas for mapping and data analysis.

Aiding University with LiDAR System

HECTIC completed a custom-build for Newcastle University - integrating a DJI Matrice 600 Pro with a LiDAR system by designing a custom-mounting solution. This was done thanks to HECTIC’s rapid in-house prototyping.

LiDAR is a sensing technology that utilises light waves from a pulsing laser to capture minute measurements, which can then be used to create detailed 3D maps and models for a variety of different applications.

Newcastle University planned to use this for numerous monitoring missions, including landslides, erosion and deformation and tree health.

Maria Valasia Peppa

Newcastle University

"Heliguy helped our Geomatics Group to choose and purchase the drones that are suitable for the group’s current and forthcoming research projects. The Heliguy employees have shown high expertise and great willingness to design mounting solutions of different sensor payloads."

Helping the James Hutton Institute

We helped the James Hutton Institute - an interdisciplinary scientific research institute in Scotland - by integrating a drone with a Sony A7R, thermal and MAIA multi-spectral camera. The multi-spectral camera also has a triggering system, which allows users to begin triggering the camera from the drone controller.

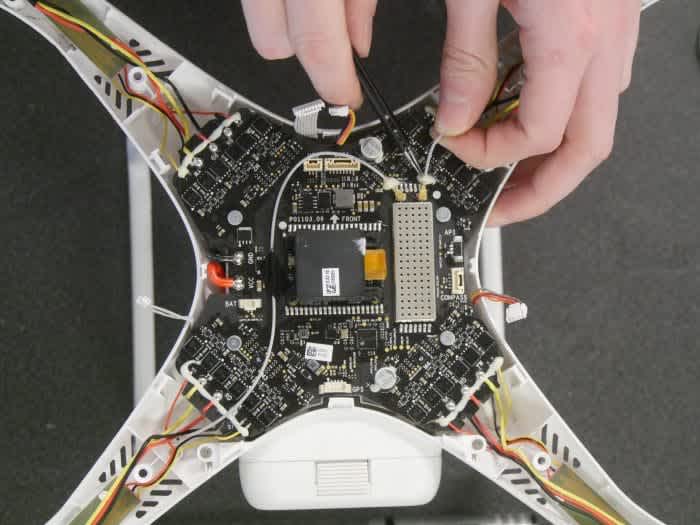

DJI Phantom 4 and Parrot Sequoia Sensor

This agricultural sensor was mounted to the DJI Phantom 4. The build included a custom mount, power solution utilising the drone's battery and a solution to GPS interference.

IMG_9699-700x467.jpg

IMG_9700-700x467.jpg

IMG_9703-700x467.jpg

IMG_9709-700x467.jpg

IMG_9711-700x467.jpg

IMG_9710-1-700x467.jpg

Slow-Mo Camera on a DJI Matrice 600

HECTIC created a custom mount, triggering system and live video transmission solution for this advanced slow-motion camera on the DJI Matrice 600.

IMG_0192-1-700x467.jpg

IMG_0194-1-700x467.jpg

DJI Matrice 210 and a Parrot Sequoia

The Parrot Sequoia was also mounted to the DJI Matrice 210 drone using a custom 3D-printed mounting case and custom power solution.

Hot-swappable Tool for National Geographic Documentary

Experienced drone pilot Oliver Sugars purchased a DJI Inspire 2 with DJI Zenmuse X7 camera and lens set from Heliguy for a two-week trip to Jordan, to film scenes for a National Geographic documentary.

Before setting off, he asked Heliguy to create a tool to enable him to utilise the hot-swappable function of the Inspire 2. HECTIC set to work and created this very device.

And it came in so useful, the bespoke tool has earned a permanent place on Oliver’s belt when he is working. The hot-swappable tool is now available to buy from us.

Oliver said: "I wanted to utilise the hot-swappable functionality of the Inspire 2. To do this you need a specifically shaped tool that I currently couldn't find on the market. So I asked the people at Heliguy if they would be able to make one for me.

"Having the ability to hot-swap the Inspire 2 batteries makes the turnaround from battery changes exponentially faster - you do not have to turn the aircraft off, thereby maintaining all settings and the craft does not have to reboot and re-calibrate the IMUs and gimbals etc.

"It means that from landing with low battery to taking off with a new full set can be a matter of seconds. This is helpful on set when all elements of a shot are on standby ready to shoot and waiting for you.

"The tool that Heliguy produced works well and is small enough to fit on your key ring. I personally attached it to a retractable key-ring, keeping it out of the way when not needed, but very accessible and easy to use when required.

"This tool allowed me to get the craft back in the air and to continue filming complex scenes that required a lot of choreography, with minimal downtime. This is important on a big set as time is of the essence."

I would highly recommend this tool as it is small and inexpensive. Anyone using the Inspire 2 in the film or television industry should have one in their kit.

Oliver Sugars

If you would like HECTIC to help you, then please submit an inquiry

A view from the HECTIC team

HECTIC is being driven by Heliguy's Research and Development Associate Ross Embleton.

He has vast experience in the industry and his previous clients include NASA, the European Space Agency and the BBC.

Ross is excited to be involved with HECTIC and believes that it will be a vital service.

He said: "HECTIC is the newest department in Heliguy, championing a fresh perspective on custom technology creation and integration.

"This exciting new venture allows Heliguy to reactively fill holes in customer experience and completes the Heliguy ecosystem.

"We can now cater for each and every individual's needs as they arise, providing access to brand new technology, thanks to our team of experienced and passionate engineers."

HECTIC Project Timeline

There are various turnaround times, depending on the type of your project. The project timelines are as follows:

Micro Project

0-9 hours development time

One-off micro-projects for a pre-determined solution to be implemented by HECTIC. For example, a small customised tool.

Small Project

10-50 hours development time

One-off small projects for specific parts with a specific purpose in mind. This could include a camera integration triggering system.

Medium Project

51-200 hours development time

Larger projects with custom integrations, prototypes and more ongoing consultation. Examples include a custom sensor control system, ground-based buggy with payloads and fixed-wing projects.

Large Project

200+ hours development time

Development of new technology for applications that require more prototyping and development type. These are from-scratch and truly-custom projects, when off-the-shelf projects don't exist.

HECTIC Project Step-by-Step Guide

You have an idea or requirement for a project.

Contact us and set up a phone call with our technicians to discuss the project requirements.

The project proposal/feasibility study is developed and a follow-up discussion is held to thrash out the details. A mutual agreement is then signed by both the client and Heliguy.

The project begins, with periodic reports produced to keep you updated on the progress of your project.

Once the functional prototype is complete, you can test the solution Heliguy have produced to make sure the concept is being delivered upon. You can then decide whether to move forward to the next phase.

Once the final product is completed, HECTIC will ask you to write a report on your experience using HECTIC and any changes you would wish to see in future projects.

Non-disclosure Agreements

HECTIC is working on a number of exciting projects which are under NDA. While we can’t disclose too much about them at the moment, we can say that our research and development team is creating bespoke builds for a variety of sectors, including construction, security and the emergency services.

At HECTIC, we know how sensitive some projects can be, so we are happy to enter into NDAs to ensure our clients’ ideas are kept secret. We won’t say a word to the outside world, until we are instructed otherwise.

If you would like HECTIC to help you, then please submit an inquiry